Compliance 101 Series – Part 2

In the world of product manufacturing, ensuring Product Safety and Certifications is paramount. This article serves as the second part of a series that we call Compliance 101. We take you through a fictitious product from the plug down the cord and into the product, cover items such as common construction requirements, testing and what to watch out for with Materials and Components. In the end it will be a primer on the basic requirements for Product Safety and Certifications no matter where in the world you are going.

The Basics

The world of Product Safety and Certifications can be a quagmire, quite confusing and downright not fun. We break it down here. Follow these 7 Tips and you will have a successful Certification program no matter where in the world you are going.

#1 – The first rule in Product Safety Certifications? READ THE STANDARD. This seemingly obvious step is often overlooked but is the foundation for all further actions. Nine out of ten products fail the first time through a Certification process because the product was not designed with the Standard in mind.

#2 – Start early in the design process. From concept is ideal. You can identify the Standard(s), read through them and build the requirements and testing that will be required into the design. Measure twice, cut once is the old adage. We call it Design for Safety Approvals – DFSAtm.

#3 – Have UL 746C in your knowledge bag of tricks. UL 746C is Polymeric Materials – Use in Electrical Equipment Evaluations. It is a reference Standard for all end product Standards that use Polymeric Materials for their Enclosures.

#4 – Know the common tests. These tests will be conduct regardless of the end product – Normal Operation Voltage and Current Input measurements, Normal Operation Temperature testing – all critical components, polymeric materials, wiring, PCB’s, etc. will have thermocouples on them to verify their temperature limits are not be exceeded, Dielectric Withstand testing will be conducted to be sure there are no live parts in contact with ground, Mechanical Abuse testing either Drop or Impact, Tip over, stability, etc., all products are also subjected to Abnormal Operation such as Locked Rotor for motor operated products, shorted thermostat for heating type products, among others.

#5 – Instruction/Installation Manuals – All products require them. Most Standards are very explicit what is required to be in them. Some Standards have the requirements buried in various construction requirements throughout the Standard. READ THE STANDARD!

#6 – Markings – All products require them. Most Standards are very explicit what is required to be in them. Some Standards have the requirements buried in various construction requirements throughout the Standard. READ THE STANDARD!

#7 – Nameplate – A nameplate is typically required with the following information being required –

- The manufacturer’s name, trade name, or trademark;

- The date or other dating period of manufacture not exceeding any three consecutive months;

- A distinctive catalog or model number, or the equivalent; and

- The electrical ratings.

Those seven tips will carry you far in the world of Product Safety and Certifications. Now we take you through the fictious product from the Plug down the Cord and then inside the product. This episode will focus on Hared-wired Supplies.

Understanding Hard Wired Supply

In the realm of product safety and compliance, understanding the basics of hard-wired supply is essential. Whether you’re a manufacturer, designer, or consumer, grasping the fundamentals of hard-wired connections ensures that products are not only functional but also safe for use. Let’s delve into the key aspects of hard-wired supply and why it matters.

Hard Wired Supply: The Basics

Hard-wired supply refers to the method of connecting electrical products directly to a building’s electrical system, typically without the use of a plug and cord. Here’s what you need to know:

- Requirement: Hard wiring is necessary when a product is permanently mounted to a building structure. However, there are exceptions. In certain cases, such as frequent servicing needs or connection to moving parts, a cord may be required.

- Enclosure Standards: Enclosures for hard-wired products must meet specific standards. Polymeric enclosures, for instance, should be 94-5VA or B rated, or tested to pass equivalent standards, ensuring durability and safety.

- Connection Methods: A suitable means of connection to the electrical supply must be provided. This can include 6-inch pigtail leads or terminal blocks, facilitating a secure and reliable connection.

- Portability Considerations: Using keyhole slots for mounting offers flexibility. Products with keyhole slots can be easily mounted and dismounted without the use of a tool, allowing for the use of a cord and plug instead of hard-wiring to an outlet box.

Key Safety Measures

When it comes to hard-wired supply, safety is paramount. Here are some crucial safety measures to consider:

Grounding: Ensuring proper grounding is essential for electrical safety. The main supply ground shall be secured to the frame. Grounding must be independent of other ground wires, with bonding materials selected to prevent corrosion or poor bonding. If other ground wires are needed, the main ground shall be connected first with it’s own nut, then the other grounds can be stacked. The idea is to not lose the main ground during servicing.

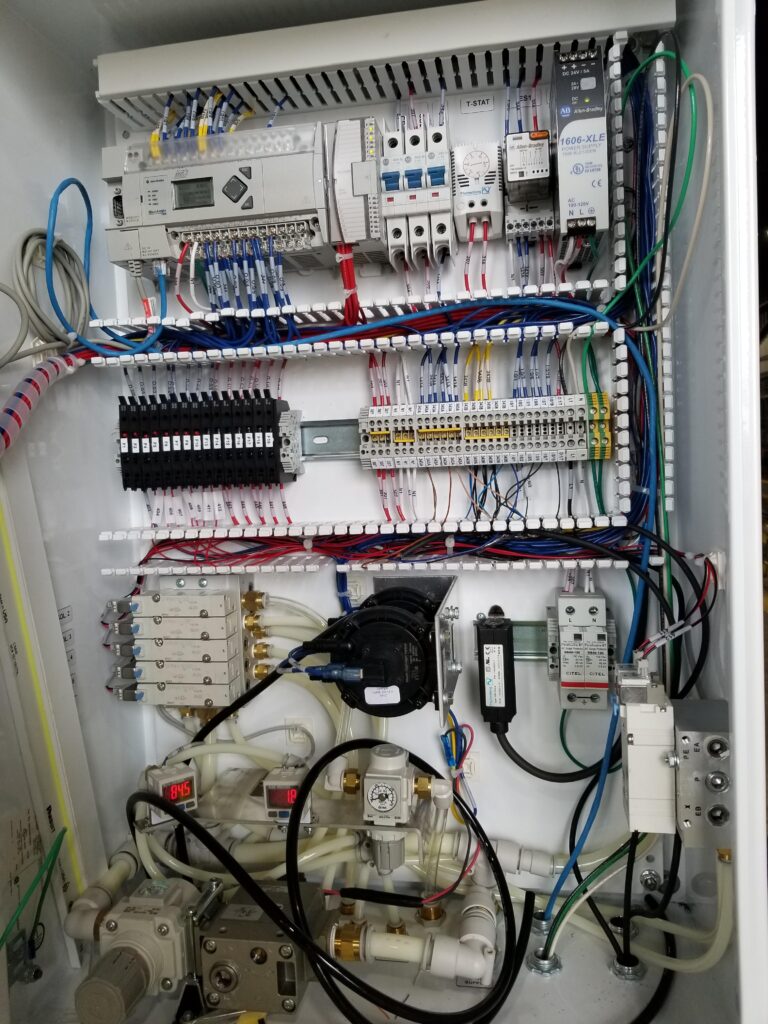

Wiring Separation: Factory and field wiring should be kept separate to prevent mixing. Design setups should ensure that the supply is separated, with panels bringing power in from the top and fixtures having a separate wiring compartment. When line voltage wiring contacts low voltage wiring either separate them or be sure the low voltage wiring is rated for the line voltage.

A maximum 6-foot whip (Flexible Metal Conduit) is typically req uired in all Standards.

Disconnect Instructions: If no disconnect is provided, clear instructions for wiring suitable to disconnect must be included. This ensures that maintenance or repairs can be conducted safely.

Terminal Marking and Grounding: Terminal blocks should be clearly marked for easy identification (e.g., L1, L2, L3).

Understanding Critical Components is paramount.

Certain components are indispensable for the safe operation of electrical products. These include those in line voltage circuitry and low voltage components relied upon for safety functions, such as interlocks and emergency stops. Ensuring the integrity and functionality of these critical components is paramount for product safety.

Ratings and Standards

All components must be used within their specified ratings, encompassing voltage, current, and frequency. Some standards may even require components to be de-rated to ensure safe operation within the intended circuitry. Adhering to these ratings mitigates the risk of component failure and potential hazards.

Mechanical Securement

Mechanical securement of components is essential to prevent dislodgment or failure during operation. While soldering is a common method of connection, it may not provide sufficient security. Mechanical fastening methods ensure robust attachment, enhancing the reliability of the product.

In the complex world of product safety and compliance, attention to both hard-wired supply principles and component selection is essential. Manufacturers must adhere to standards, implement key safety measures, and follow best practices to ensure products are not only functional but also safe for consumers and the environment. Understanding the basics of hard-wired supply ensures that products meet rigorous safety standards and remain reliable in various applications.

Moreover, meticulous attention to detail in component selection and usage is paramount. By comprehending the role of critical components, adhering to ratings and standards, and ensuring mechanical securement, manufacturers can uphold the highest safety standards. Verification, certification, and adherence to specific considerations reinforce the integrity and reliability of electrical products, instilling trust and confidence among consumers. Whether designing, manufacturing, or using electrical products, thorough knowledge and adherence to safety principles are indispensable for ensuring product safety and compliance.